44 years - AirGraver History

-

by Steve Lindsay

History of Lindsay's gravers was originally written in 2000 and still resides

where the AirGravers were first introduced and sold.

(link)

Click to enlarge photos

The AirGraver

tools are a culmination of 44 years of engraving and tool making by Frank and

Steve Lindsay. In

1975, at the age of 17, Steve began to learn hand engraving with his father

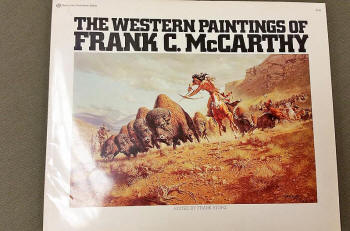

who is a watchmaker and jeweler. Frank became friends with John Rohner and James (Bruce) Meeks. At that time

he purchased John Rohner's

invention called a Gravermeister from John in Boulder Colorado. John's

invention was the world's first pneumatic engraver. John Rohner was a

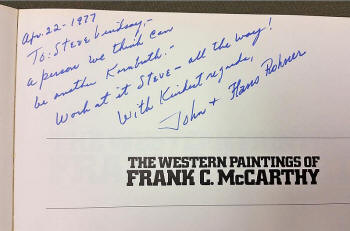

supporter encouraging Steve to continue learning. Above is a book John

signed in 1977 which was an inspiration to Steve.

The AirGraver

tools are a culmination of 44 years of engraving and tool making by Frank and

Steve Lindsay. In

1975, at the age of 17, Steve began to learn hand engraving with his father

who is a watchmaker and jeweler. Frank became friends with John Rohner and James (Bruce) Meeks. At that time

he purchased John Rohner's

invention called a Gravermeister from John in Boulder Colorado. John's

invention was the world's first pneumatic engraver. John Rohner was a

supporter encouraging Steve to continue learning. Above is a book John

signed in 1977 which was an inspiration to Steve.

In 1977, after graduating from high school,

Steve enrolled in the same Nebraska tech college that his father attended studying watch making.

Steve enrolled

in machine tool and die on the recommendation of John Rohner.

The college and super instructors (i.e. Alan Carter) allowed students to use

the school's machine shop for personal projects in the evening. Taking that

opportunity, Steve created several new hand pieces for the Gravermeister that

he was using. The new hand pieces were palm-sized rather than long. This was

beneficial for smaller, detailed engraving as well as providing improved

control. In 1979, Frank designed an electronic circuit to

oscillate and adjust the speed of a solenoid valve. Air was run through the

valve to produce blow-pulses rather than suction-pulses. Frank made two of

the machines. Steve used the school's machine tools to build

various hand pieces for Frank's adjustable positive pulse generator.

In an interview for the December, 1981 NebraskaLand magazine, Frank's machine

was mentioned and a picture of it can be seen on the back corner of the engraving bench on page five of the article.

NEBRASKAland.pdf

It is the gray box in the

right back corner of the bench. The hand pieces hidden for the article

and from the public for years, and until they were posted on the internet in

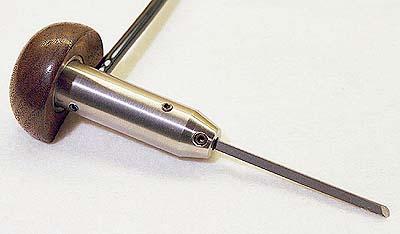

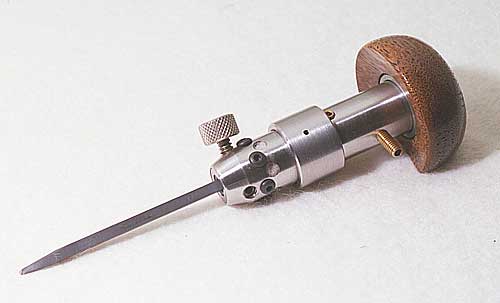

2006. At the left is a picture of three

positive pulse gravers made in 1979 for Frank's machine.

In 1977, after graduating from high school,

Steve enrolled in the same Nebraska tech college that his father attended studying watch making.

Steve enrolled

in machine tool and die on the recommendation of John Rohner.

The college and super instructors (i.e. Alan Carter) allowed students to use

the school's machine shop for personal projects in the evening. Taking that

opportunity, Steve created several new hand pieces for the Gravermeister that

he was using. The new hand pieces were palm-sized rather than long. This was

beneficial for smaller, detailed engraving as well as providing improved

control. In 1979, Frank designed an electronic circuit to

oscillate and adjust the speed of a solenoid valve. Air was run through the

valve to produce blow-pulses rather than suction-pulses. Frank made two of

the machines. Steve used the school's machine tools to build

various hand pieces for Frank's adjustable positive pulse generator.

In an interview for the December, 1981 NebraskaLand magazine, Frank's machine

was mentioned and a picture of it can be seen on the back corner of the engraving bench on page five of the article.

NEBRASKAland.pdf

It is the gray box in the

right back corner of the bench. The hand pieces hidden for the article

and from the public for years, and until they were posted on the internet in

2006. At the left is a picture of three

positive pulse gravers made in 1979 for Frank's machine.

Steve found that

the limitation to his father's design and other designs on the market be that

air or electric is that they depend on a spring in the handpiece. The spring

in these designs creates a limited power band. They have an adverse effect of

loss of power, or a complete absence of power when the piston floats, caused

by the pulses giving insufficient time for the spring to return. This is

caused by the frequency of the air or electric pulses being too fast and/or by

too much air pressure or current in each pulse. Through the mid and late

90's Steve worked on designing, and attempting to create a new device

that would give an even wider range of power and impact strokes, without

sacrificing the finesse and control my father built into his engraving

machine. The venture led Steve to research to directly using the solenoid as

the handpiece itself using the 555 timer IC circuit from Frank's 555 ic timer

pulse generator machine. The handpiece was an airless electromagnet

graver. This airless graver worked for the fine engraving, but had

limited power at the top end (or if a heavier spring is used be the same loss

of low end power occurred similar to the air pulse designs giving the same

limited power band) and also produced heat in the handpiece. Another

disadvantage to the airless design is that it is effectually an electromagnet

which causes gravers and tools to become magnetic.

Finally, by

accident, Steve happened on the current AirGraver design. The design Steve was

attempting to build then was a two valve system working together as one in a

forward direction, but he found the mechanism ran better backwards. The

challenging aspect was to create an impact pulseless engraver that did not

require either an air pulse or an electric pulse generator taking up space on

the bench, and that would oscillate with the softest whisper of air required

for microscopic engraving shading work and yet be able to muscle out the

background around a scroll design when used with much greater air pressure.

Since 1999 the AirGraver has been working for

Steve's work as well as engravers and

jewelers world wide.

After machine

tool & die school in 1979, Steve continued to engrave by day while working second shift in

the tool room of a Nebraska manufacturer. After regular hours there, he used

their machine tools and continued to refine engraving tools. He also made two

positioning vises for his

father and himself for engraving under. The diamond microscopes Frank used in

his jewelry store. In 1980 after the tools were refined

and efficient, Steve quit the factory machine tool job and began full time engraving. Another friend of

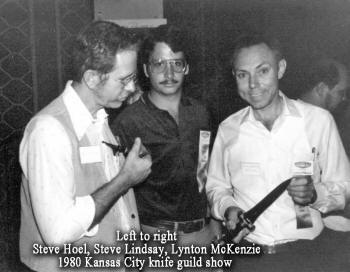

Frank's, Lynton McKenzie, recommended Steve attend the knife makers' guild show

in Kansas City in 1980.

After machine

tool & die school in 1979, Steve continued to engrave by day while working second shift in

the tool room of a Nebraska manufacturer. After regular hours there, he used

their machine tools and continued to refine engraving tools. He also made two

positioning vises for his

father and himself for engraving under. The diamond microscopes Frank used in

his jewelry store. In 1980 after the tools were refined

and efficient, Steve quit the factory machine tool job and began full time engraving. Another friend of

Frank's, Lynton McKenzie, recommended Steve attend the knife makers' guild show

in Kansas City in 1980.  He

took the top side of this

linked 9mm Browning to the show. Lynton was

at the show and took him from table to table to introduce him to knife makers and

his collectors. Knife markers such as Buster Warenski, Steve Johnson, Steve

Hoel, Ron Lake, Jim Hardenbrook and Jim Ence were at the show. From

those introductions, knife makers and collectors gave Steve engraving jobs. (some can be seen at

www.LindsayEngraving.com ). For

the next few years, Frank made more improved hand pieces with his lathes and

milling machines that Steve then used for his engravings. In 1984 or

1985 James Meeks came by to say hello and visit. He was working on his second book then and brought along

many white plastic plates. He explained the surface was white but when cut into, the lines

showed black. He had engraved them with various scrolls and example designs.

He explained he was engraving this plastic because the engraving would

photograph well for the book. After that visit Don

He

took the top side of this

linked 9mm Browning to the show. Lynton was

at the show and took him from table to table to introduce him to knife makers and

his collectors. Knife markers such as Buster Warenski, Steve Johnson, Steve

Hoel, Ron Lake, Jim Hardenbrook and Jim Ence were at the show. From

those introductions, knife makers and collectors gave Steve engraving jobs. (some can be seen at

www.LindsayEngraving.com ). For

the next few years, Frank made more improved hand pieces with his lathes and

milling machines that Steve then used for his engravings. In 1984 or

1985 James Meeks came by to say hello and visit. He was working on his second book then and brought along

many white plastic plates. He explained the surface was white but when cut into, the lines

showed black. He had engraved them with various scrolls and example designs.

He explained he was engraving this plastic because the engraving would

photograph well for the book. After that visit Don

Glaser Sr. called and said

that Meeks really enjoyed seeing my palm sized powered graver. It was an awkward phone call

because Steve did not show Meeks his hand piece during his visit. Steve

did receive a phone call while Meeks was visiting and he was left alone at the

bench for a short time. He must have

found the hand piece. It was interesting because after that Mr. Glaser

brought out a new smaller hand piece that had a plastic mushroom handle on the

butt, unlike

the hand pieces they were making that were long and straight with

a

handle midway rather than at the end. It did not matter since Steve was

not in the tool business at that time, but only engraving for collectors.

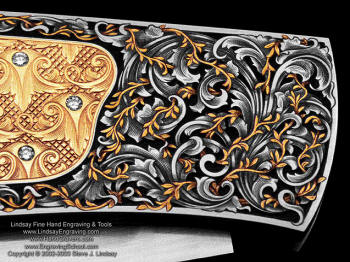

In 1987 Frank and Steve did some engraving projects together. They produced five engraved folding knives.

Steve drew the outlines of the knife designs and Frank made and set the diamonds, and

Steve then engraved them. Frank's knives

had hidden watch screws and wedges and would come apart allowing the inside

surfaces as well as the outside ones to be engraved. The five pieces

were called Lindsay-Lindsay. The Japanese knife engraving market was strong

then and several of them went to customers and dealers in Japan selling for as

much as $40,000. Later the owner of the #5 piece contacted Steve with

the news that he had a terminal illness and wanted to sell and was asking

$110,000. It was offered for sale on the

LindsayEngraving.com

site and was resold.

Glaser Sr. called and said

that Meeks really enjoyed seeing my palm sized powered graver. It was an awkward phone call

because Steve did not show Meeks his hand piece during his visit. Steve

did receive a phone call while Meeks was visiting and he was left alone at the

bench for a short time. He must have

found the hand piece. It was interesting because after that Mr. Glaser

brought out a new smaller hand piece that had a plastic mushroom handle on the

butt, unlike

the hand pieces they were making that were long and straight with

a

handle midway rather than at the end. It did not matter since Steve was

not in the tool business at that time, but only engraving for collectors.

In 1987 Frank and Steve did some engraving projects together. They produced five engraved folding knives.

Steve drew the outlines of the knife designs and Frank made and set the diamonds, and

Steve then engraved them. Frank's knives

had hidden watch screws and wedges and would come apart allowing the inside

surfaces as well as the outside ones to be engraved. The five pieces

were called Lindsay-Lindsay. The Japanese knife engraving market was strong

then and several of them went to customers and dealers in Japan selling for as

much as $40,000. Later the owner of the #5 piece contacted Steve with

the news that he had a terminal illness and wanted to sell and was asking

$110,000. It was offered for sale on the

LindsayEngraving.com

site and was resold.

Lynton Mckenzie

and Steve engraved a SCI Safari

Club International rifle project together. David Miller was the maker, Lynton

engraved the rifle and Steve did the accessories and a Steve Hoel folding knife

that were cased with the rifle. The piece sold at auction for

$210,000. There is a photo of the accessories

at link. Click

the photo there to enlarge,

link.

Lynton had also been engraving Gene Clark's

watches. When Lynton became sick in early 1998 he recommended to Gene that

Steve engrave

them. Steve engraved three of Gene's watches. An improved AirGraver design

was completed while working on the second one.

That second one was auctioned at Sotherby's and sold for $62,500.

LindSayengraving.com/Clark.htm

Through the years the AirGraver continued to be improved.

There is a video

of one of Gene's watch faces being engraved in the above link.

Lynton had also been engraving Gene Clark's

watches. When Lynton became sick in early 1998 he recommended to Gene that

Steve engrave

them. Steve engraved three of Gene's watches. An improved AirGraver design

was completed while working on the second one.

That second one was auctioned at Sotherby's and sold for $62,500.

LindSayengraving.com/Clark.htm

Through the years the AirGraver continued to be improved.

There is a video

of one of Gene's watch faces being engraved in the above link.

Various AirGraver designs.

1. The self oscillation

pulsefree AirGraver piston principle was patented. It can operate with very little air

pressure or air volume. In fact, by simply blowing in it. Even attached to a toy balloon, the tool will idle. Instead of a

spring for the return or impact stroke, the device uses air pressure for both

directions. As a result, the piston always stays balanced and low or high air

pressures can be used without one side overpowering the other causing the piston

to float, which can occur with the spring-pulse designs. The patented idle of

the new design prevents jumps that sometimes occur with spring-pulse designs.

The stroke length and speed adjustment is in the bore of tool. Adjustment is

made by removing the graver and adjusting the screw at the bottom of the tool

hole.

2. A multiple controller box is shown above. Since this box required a lot of work to

manufacture, it was replaced by using either a simple toggle-routing valve on the current foot controller setup, or quick disconnects. This development allows as many

hand pieces and rotaries as needed to be operated at the same time.

3. One way to move the length-of-stroke adjustment to the outside of the hand

piece was the ring pictured above. Only one of these was made as a prototype and

it was patented when the snap on/off handle was patented. The tool worked nicely,

but it was difficult to make and assemble because of all the small internal

parts.

4. In the design shown above, stroke adjustment was still in the tool hole, but

the addition of the black rings around the body made it possible to adjust the

exhaust by turning the ring. When a stroke adjustment was made, the exhaust

could also be tuned to make them run even better.

The stroke adjustment on the tools makes one hand piece as versatile as a

variety of different-sized hand pieces.

5. Away to adjust the

stroke by moving the nose in and out with a ring around the body, while

simultaneously adjusting (tuning) the exhaust was an additional patent.

Synchronizing the two made the tool run well throughout the stroke range,

without having to adjust one and then the other. The ring works in a manner

similar to focusing a lens on a camera. Because of the way the nose is held in

place, the impacts are isolated to the nose and graver shank. This leads to less

vibration to the body during impacting, and provides significantly more power

when needed.

The stroke adjustment is similar to gears in a car and makes the tool perform like numerous handpieces

in one. First gear is good for shading and fifth gear is good for background. If

thinking about it this way, the old pulse machines similar to my father's machine has

one gear.

6. The development of the PalmControl meant the

elimination of the foot pedal. I noticed that while engraving with a foot pedal,

engravers also vary the pressure used to hold the graver point in a cut.

Depending on the depth, engravers vary the amount of palm pressure. This idea

was built upon by making a handle that would automatically respond to the palm

pressure to operate the throttle. The concept for the PalmControl was: why do we

have to duplicate with a foot pedal what our hand is already doing? It was also patented. The legal enforceable claims of the patent protect a hand push pressure activated power tool used in the

hand engraving and jewelry fields.

Link to the PalmControl AirGraver page